Larry,

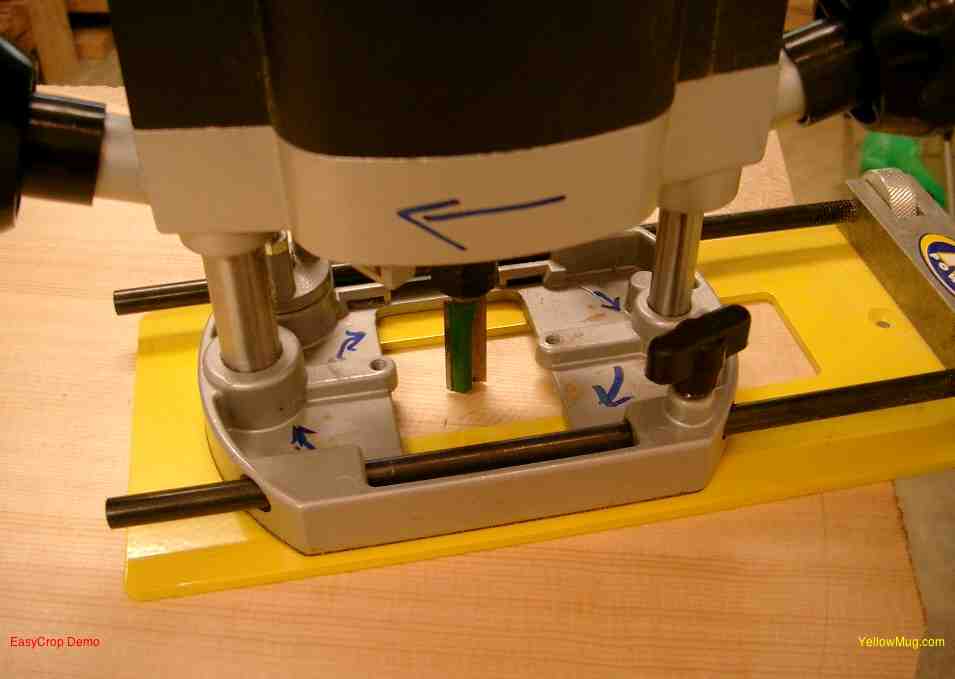

Another option is to use a dremel with the dremel circle cutting jig. I think it was less than $20 for jig straight from dremel website, and free shipping. I just use a 1/8" downcut bit. Here is a pic of it:

I actually use the stewmac circle cutting jig for the dremel on guitars, but this was for a Uke, and the smallest diameter that the stew mac base will make is 3"(I think). I know it won't do a 2" diameter sound hole.

Couple of things to remember. Always start your cut under the fretboard extension. This way if you screw up, it will be covered by the extension. I also, first make the cut in the center of the rosette all the way around only taking 1/2 mm of depth. Then lower to correct depth and cut again. Then I turn the bit so it is at its widest cut, and place back into the rosette channel. I loosen the knob and push the bit against the rosette wall, then tighten the knob. Make another pass and keep doing this until the rosette fits. Then I go the opposite way, and do the same thing. This is what I call easing into the final cut.

Also, do a test cut of the rosette in a piece of scrap and make sure you can fit the rosette in the scrap first before touching the top. This way you will understand the process and know exactly what will work.

In the pic above, this rosette fit so tight in a few places, that I had to hammer it in. So I was very pleased with the result. Anyway, good luck!

Tracy

|

Easy to use and adapts to many types of routers for $31.50 Can, less in US dollars!

Easy to use and adapts to many types of routers for $31.50 Can, less in US dollars!